Banks Engineering & Machine

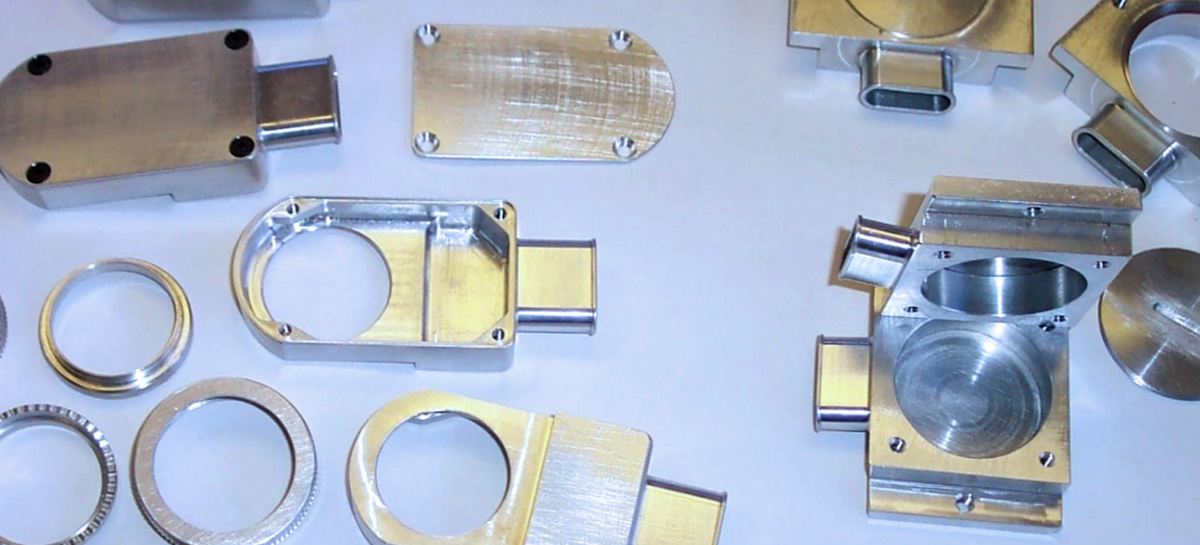

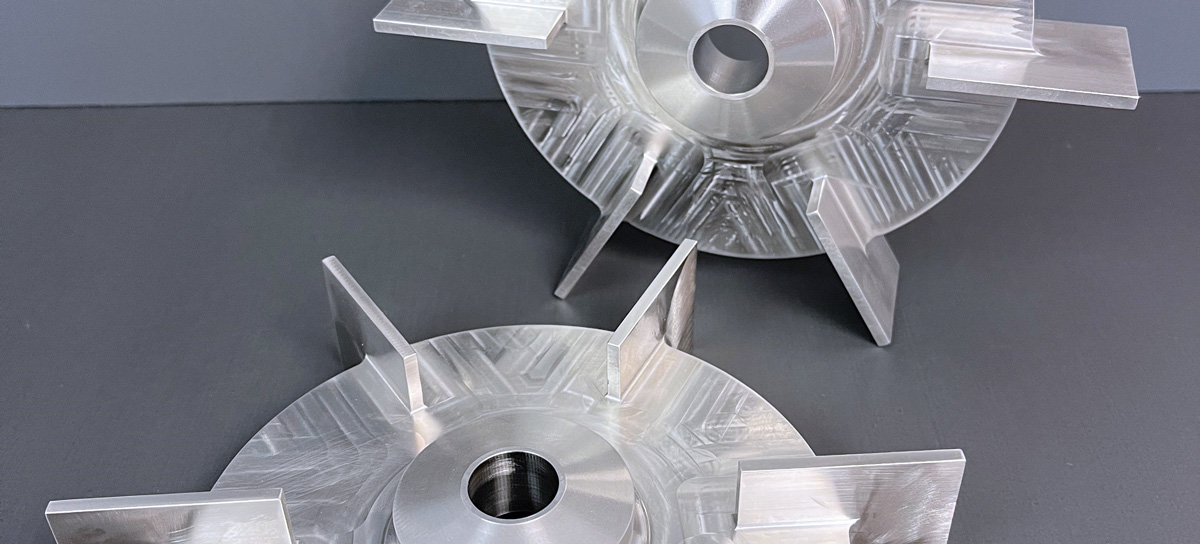

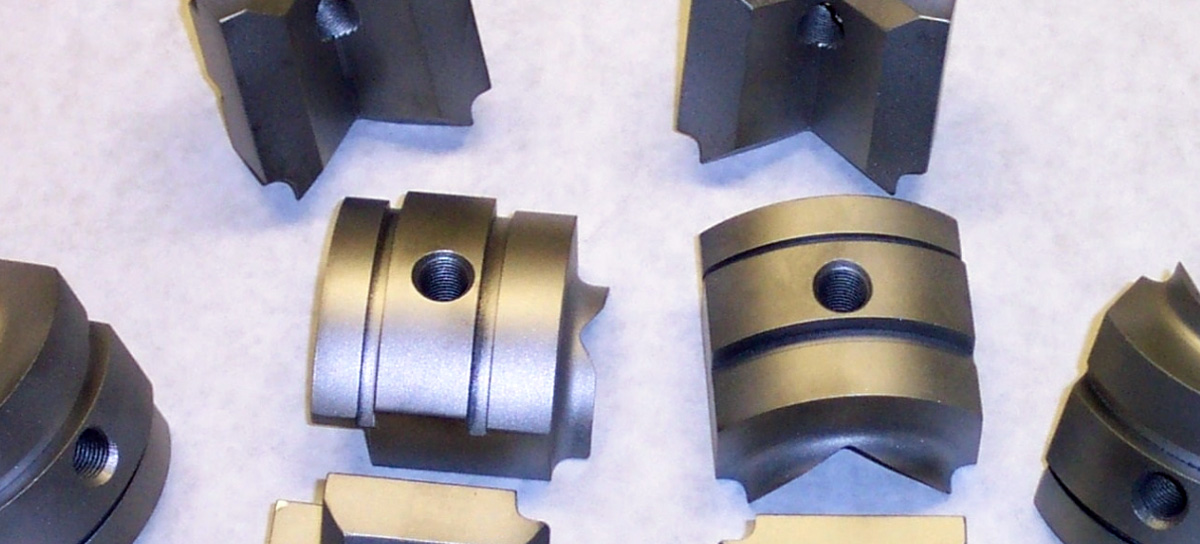

A full-service machine shop capable of one off to full production.

We are ISO-9001: 2015 Certified.

Banks Engineering & Machine was incorporated in late 2020 with partners TJ Banks & Ross Turner. TJ & Ross were former colleagues at Leggett & Platt. The team oversaw and led the expansion of production at the Carthage operation which supplied most of the Automotive Tier 1 and OEM car/truck manufacturing facilities for vehicle interiors in North America.

Mission

Mission Statement

To be the region’s most reliable business providing the best machined parts and engineering services.

Banks Engineering & Machine was incorporated in late 2020 with partners TJ Banks & Ross Turner. TJ & Ross were former colleagues at Leggett & Platt. The team oversaw and led the expansion of production at the Carthage operation which supplied most of the Automotive Tier 1 and OEM car/truck manufacturing facilities for vehicle interiors in North America.

TJ & Ross established BE&M with the intent to purchase the Wyandotte Precision Products machine shop located at the Joplin Airport. This shop served the greater Joplin and 4-State area with primarily repair support. Principles being in the food production and support industries. The acquisition was completed in Feb 2021.

In late 2021 BE&M completed the asset purchase of American Tool & Engineering. The company primarily focused on Tool & Die and Production Fixtures. BE&M has completed the consolidation and continues to serve the ATE customer base.

Since these purchases BE&M has successfully taken production projects that service customers beyond the 4-State area – across the United States.

Capabilities

Capabilities

- Design Engineering

- Reverse Engineering

- 3D Modeling

- CAD/CAM

- Automation

- PLC Programming

- Consulting (Processing/Cycle Time/Efficiencies/Lean Manufacturing)

- Machining/Grinding

- Tool Making

- One Off to High Volume Production

- Welding (Sanitary Welding)

- Fabricating

- Emergency Repairs

- Materials: Steel/Plastics/Phenolics/Stainless Steels/Aluminum/Exotic Steels/Bronze/Brass

Equipment

Equipment

- Milltronics Vertical Mill

- VM 20 – (40” x 20”)

- VM 4020 – (40” x 20”)

- VM 17 – (30”x15”)

- VM 2515 – (25”x15”)

- VMD 30 – (100” x 30”)

- Partner 6 – (40”x20”)

- 2 Partner 1 – (30”x15”)

- Doosan Lynx 2600Y – (10” Chuck, Live Tooling, Y-Axis)

- Milltronics SLA 8 – II (8” Chuck)

- ACE Jobber XL – (8” Chuck)

- Milltronics ML-26 (12” Chuck)

- Milltronics ML–15 (8” Chuck)

- Milltronics ML-22 (12” Chuck)

- Lucas Horizontal Boring Mill

- 4 – Bridgeports

- Vertical 60”

- 4 – Manual

- Blanchard 24”

- 3 – Flat Grinders

- 1 – Cylindrical OD Grinder

- 2 – Gear Hobs

- TIG/MIG/Arc

BIOs

Timothy Joseph Banks (TJ)

Partner – President of Operations

Graduate from University of Rolla (UMR) in 2010 - Bachelor of Science and Mechanical Engineering (BSME).

While in college he completed an internship with Schlumberger performing Oil Field services monitoring well performance.

At Finley Engineering he was Field Engineer, Project Management for Fiber Optic Network to Home installations.

TJ worked as Machine Design Engineer Manager for Leggett & Platt Automotive Group in Carthage MO, designing, building and deploying fully automated manufacturing sells to supply the automotive industry with seat suspension products. He managed the build and operation of the tool and die machining department to fabricate the equipment and service all machinery – Comprised of Wire Benders, Material Load and Handling Robots, Mold Presses and Plastic Mold dies.

After leaving Leggett & Platt in late 2019 TJ joined ICR in Troy MO as the Engineering Manager designing, building and deploying automation solutions to the Automotive foundry finishing sector.

In late 2020, TJ and Ross formed Banks Engineering & Machine LLC with the purpose of purchasing Wyandotte Precision Products.

Ross Turner (Ross)

Partner – President of Business Development

Graduate of Embry Riddle Aeronautical University with an MS in Aeronautical Science in 1987.

During his BS and MS work Ross was serving in the USAF as an Airborne Radar and Avionics Technician.

Upon completion of his tour, he went to work for McDonnell Douglas Helicopter in Mesa AZ as a Senior Quality Engineer and then ultimately a stint in the United Kingdom as the Manufacturing Technical Lead supporting the build of the United Kingdoms version of the AH 64 Apache Attack Helicopter. McDonell Douglas and Boeing merged in 1998 where Ross took an opportunity with L&P and left as a Boeing employee.

Ross had two terms of employment with Leggett & Platt with a 5-year stint between while running a Heading and Wire Forming factory in Washington Iowa.

During his second term with Leggett & Platt is when Ross & TJ form a friendship which ultimately led to BE&M.

Contact Us

Office Manager: Courtney Banks

Banks Engineering & Machine

5502 Dennis Weaver Drive

Webb City MO, 64870

Office: 417-625-1844

Website: Banksem.com

TJ Banks : tjbanks@banksem.com

Ross Turner: rossturner@banksem.com

Courtney Banks: courtneybanks@banksem.com

Shoot us a message here:

"*" indicates required fields